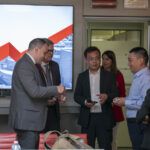

Deputy Secretary of the Party Committee and General Manager of Fengpu Development Zone Gu Weixing, along with senior officials Hu Yefeng, Hu Chunni, Gao Zhong, and You Ji, visited Elemaster Headquarters in Lomagna yesterday. This visit is part of a European tour during which the delegation is visiting companies with a presence in the Fengpu Industrial Park, including Elemaster Shanghai.

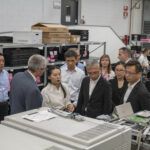

Elemaster Shanghai, selected among numerous companies to establish its presence in this prestigious area, has been a market leader for over a decade. The visit highlighted Elemaster’s commitment to technological innovation, showcasing its capabilities and mission.

Elemaster Shanghai President Luca Ceppi warmly greeted his guests and was delighted to showcase Elemaster’s work during their visit.

“We were really honored to receive this prestigious visit and to welcome the whole delegation of the Fengpu Industrial Park” commented the Elemaster Shanghai President.

“A rare occasion to show our Headquarters to Deputy Secretary of the Party Committee and General Manager of Fengpu Development Zone Gu Weixing and his delegation” Added Sergio Bonacina, Elemaster Shanghai General Manager “A way to affirm the strategic significance of Elemaster Shanghai within the global manufacturing landscape and its dedication to excellence in technology.”

About Fengpu Industrial Park:

Shanghai Fengpu Industrial Park is one of Shanghai’s nine municipal-level industrial parks, covering over 50 square kilometers in two sections. Over the past decade, it has become a hub for industries like electronic and communication equipment, electrical machinery, and metal products. The park hosts renowned companies, leaders in their sectors like Elemaster Shanghai.

About Elemaster Shanghai:

Elemaster Shanghai replicates the processes and technology of its Italian Headquarters at its production plant in Shanghai, ensuring consistent quality and efficiency in the production of PCBA and integrated systems. Services offered include fast prototyping, SMT and THT assembly, conformal coating, IN CIRCUIT testing, functional testing, X-ray inspection, burn-in testing, and electromechanical integration. In 2022, the company received ISO 13485:2016 certification for Medical Applications, an international standard that outlines a quality management system specific to the medical devices industry, and joins the more historical certifications related to the Railways world (ISO/TS 22163:2017) and to the one of Energy & Automation (ISO 9001:2015), making this location more and more competitive and committed to Customer needs.