Safety is an absolute and unavoidable value for Elemaster. Designing and producing for safety is part of its mission and objectives. Security in technology, security in organization and financial security. Customers in the railway industry who rely on Elemaster can count on the strength of a strong and healthy organization. The certainty that their product will be taken care of with the utmost care in all aspects.

Design and simulation: first step for safety

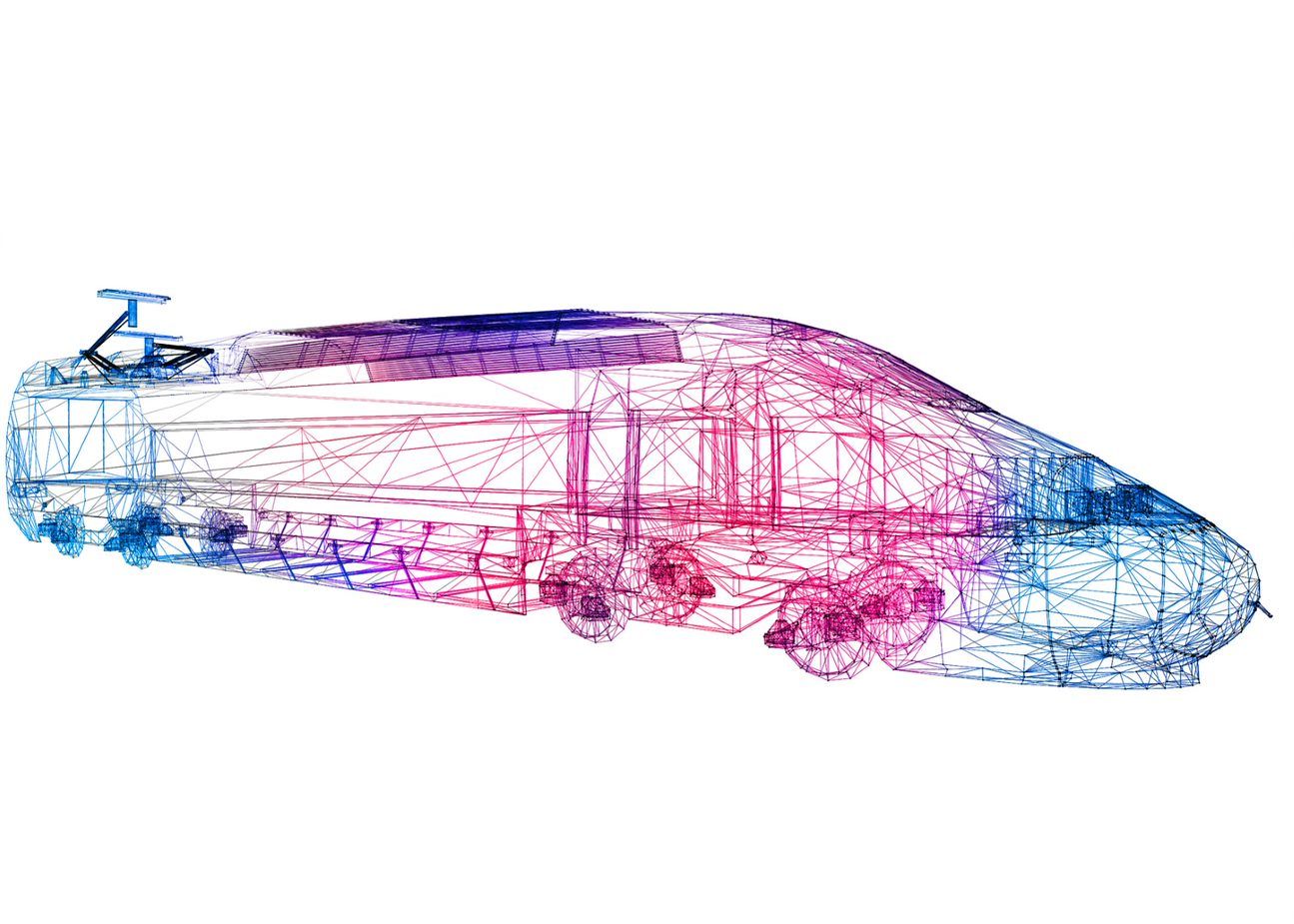

Security in Elemaster starts with design. Designing functional safety means using devices and software that can process mathematical functions and algorithms that allow highly accurate operation simulations. In the case of sensors that will be installed on a train travelling at 350 km/h, it is a question of simulating the performance in relation to environmental and functional stimuli according to certain mathematical parameters. For example, it is possible to simulate environmental conditions such as temperatures of sixty-five degrees, or the occurrence of a sudden acceleration due to a track that is not perfectly connected. In this way, Elemaster can visualize and verify that the design dimension covers all situations that may occur in the installation field. Any intrinsic weaknesses of the design which may affect safety and efficiency can thus be resolved.

Elemaster uses EDA, CAD, CAM systems: software with technological modules of design and simulation, which allow to manage information from design to production verifying a priori its effectiveness and compliance with the specifications requested by the client.

Technological Companions: A.R. and A.I.

Thanks to this approach, it is possible to virtually design not only the components of an electronic board but the entire train. Thanks to augmented reality and artificial intelligence, guided maintenance can be activated. For example, with Google glasses or other multimedia devices, you can apply maintenance manuals by showing the operator which parts and components to check.

3D Printers for prototyping

Thanks to the use of 3D printers, Elemaster’s design reduces prototyping and testing times by months. After drawing it, the electronic card is printed in 3D and together with it is also produced the card container and e.g., on a small scale the kinematic parts that the electric motor moves. The Elemaster designers develop a simulation that can rely on a physical sample in addition to CAD visualization. This allows you to immediately check that everything conforms to the predefined standards and specifications. This approach not only significantly reduced costs, but also significantly reduced the gap between the design assumptions and the actual final production result.

The Elemaster development process allows you to build the physical part using different materials such as plastic, metal, ceramics. Not only that: it is possible to make a sample of the product which will then be placed on the market in the scalar dimension considered most suitable. A huge benefit for the customer: within a few weeks you will have a precise idea of how your product will look like. Above all, the customer will be aware of how the solution corresponds to the specific requirements. Another great advantage is the fact that by adopting this design method, it is possible to estimate the cost of the product in all its phases of development with exact accuracy.

Quality and speed: two key points of Elemaster approach

A unique and innovative design approach that offers great value of customer service. Thanks to “having” the finished part, after only three weeks from the start of the project, the client will have the opportunity to evaluate not only the functional but also the ergonomic and aesthetic parameters, i.e., all the elements that define the industrial design of an item.