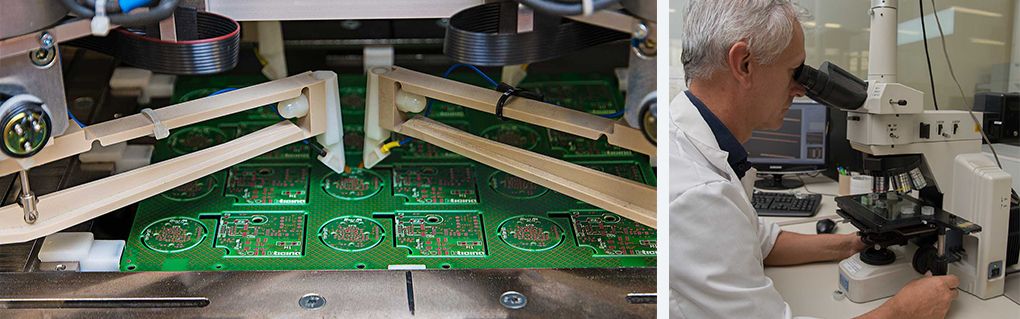

Eleprint laboratory, in order to guarantee the best quality of printed circuit boards, allows to carry out metallographic sections, chemical tests, thermo-mechanical analysis and electrical tests, as well as non-destructive tests for the measurement of metal thicknesses on the surface and in the holes.

Chemical tests

To check the products, the following chemical analyses are performed:

- Analysis of qualitative data of the concentration of organic substances by means of spectrophotometer according to the regulations in force.

- Analysis for controls and management of production lines.

- Analysis of organic substances in electrolytic line through CVS.

Thermo-mechanical analysis

For the control of the construction and reliability of the circuits, TMA is defined:

- TG

- Delta TG

- TTD

This ensures the best choice between different options, so you can define the ideal material to achieve the exact performance you want.

Electrical and electronic analysis

Electrical and electronic analysis of printed circuit boards and impedance control are used in various applications to ensure the integrity of high frequency signals.

ATG flying probe machines are used for electrical testing.

Eleprint laboratory measures and analyses the impedance of the circuits using the CITS Polar instrument.

Nondestructive testing

The following measurements can be taken with the help of trained CIS IPC-A-600 trained operators and the supervision of a CIT IPC-A-600 qualified internal trainer:

- Nondestructive coating thickness measurement of nickel – gold – chemical tin – HAL finishing by Fischerscope X-Ray.

- Nondestructive measurement of copper thickness in the holes by CMI (Eddy current instrument).

- Quality acceptance evaluation with CIS operators, specialized IPC-A-600.